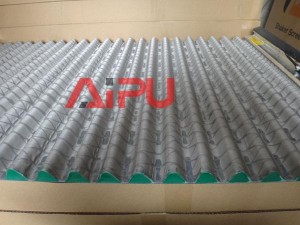

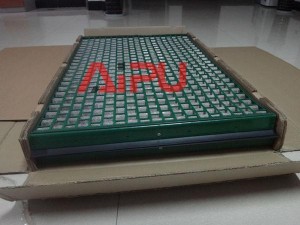

We just delivered about 400 panels shaker screens to Dubai. They are our new client…

2018

Main Types Of Shale Shaker Screen On Market Nowadays

There are varied shale shaker screens manufactured by different solids removal equipment company on market nowadays . The screens of shaker are typically totally different in either dimension or screen structure or material. So for choose the proper screens to the shakers, the knowledge of screen types is needed.

Main Different Shaker Screens for Oil Drilling Industry

At oilfield all over the world there are thousands of shaker screens. Mainly including

- Un-bonded hook strap screen

- Hard hook strap shaker screen

- Steel framed screen panel

- Composite framed screen

- Up side tensioning screen

- Back side tensioning shaker screens

According to the material of screen, there are followings screen

- Stainless steel wire mesh shaker screen

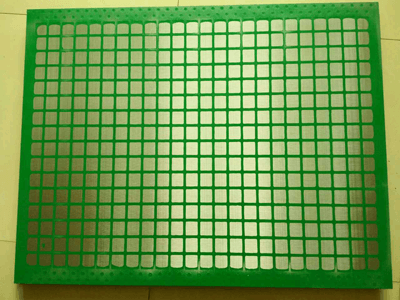

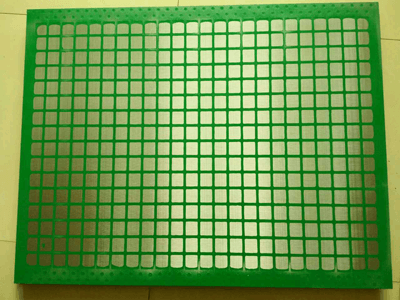

- Polyurethane screen panel

- S.S wedge wire screen

Shaker screen size

- Different shaker will be installed with screens sized differently on length, width.

- The mesh size or opening size is determined by practical working condition

Flat Screen VS Pyramid Screen

Flat Screen (PWP) and Pyramid Screen (PMD) are commonly used to describe Derrick Shaker Screen. The derrick shaker could install each varieties of screens. The flat screen is that the traditionally sort and price less whereas the Pyramid screen is of latest screening technology that may increase the fluids handling capability and improve screening performance. The pyramid has higher effective area than flat screen by two hundredth to four-hundredth.

Metal-Framed Screen VS Composite frame Screen

Frame screens are usually Metal framed screen is wide used and accepted by the industry. Since M-I Swaco develops DURAFLO composite screens in 1998, some drilling contractors like better to highly to choose to use this new screen because the stuff is more sturdy and lighter.

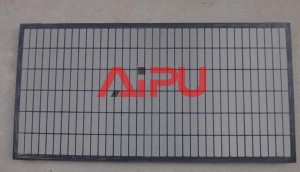

Hook Strip Screens

Vibrating Screens for classifying, sizing, straining, sieving, are usually secured by clamping rails that apply tension across the screening surface. the tension is applied through edge treatments on the woven wire cloth screen panel usually remarked as “hooks” or “hook strips”. proper screen tension is crucial for effective screening and longer screen life. Banded Hook edges increase strength (prevent flattening) and eliminate mesh pull-out on fine wire mesh or high tension screens. Hook Screens could feature one layer of mesh or a double layer, wherever a coarse mesh is a backup to a finer prime mesh, adding strength. A triple or sandwich type layered screen is additionally offered for specialised applications.

Plastic reinforcing is used in multiple layered screens when it’ll contribute to screen life.