We all know the decanter centrifuge is 4th phase solids control equipment for drilling fluid.…

2021

Drilling Fluid Rotary Single Screw Pump With 2.5Mpa Pressure

Summary of screw pump

Well drilling screw pump is mainly used to transfer drilling mud to decanter centrifuge. So wel also call it as centrifuge feed pump. It is made of hihg quality stainless steel material. Per different working condition and transfer fluids we’ll consider 304~316L or the 2Cr.13Ni., etc.

Aipu Solids Control Centrifuge feed pump is a positive-displacement pump that use one or several screws to move fluids or solids material along the screw axle. There are single screw pump, double screw pump, the triple screw pump, as well as the quintuple screw pump. For drilling mud process, we use the screw pump to transfer drilling fluid to Decanter Centrifuge from desilter tank or centrifuge tank.

Screw pump transfer drilling fluid via the Screw Conveyor rotation. Center screw pole is the positive pole, the two sides screw conveyor are negative pole. Negative poles rotate at opposite direction with positive pole.

A screw pump, also known as a water screw, is a positive-displacement (PD) pump that use one or several screws to move fluids or solids along the screw axis.

Screw pump transfer drilling fluid via the screw conveyor rotation. Center screw pole is the positive pole, the two sides screw conveyor are negative pole. Negative poles rotate in the opposite direction with a positive pole.

Screw Pump Technical Parameters

| Model | Speed | Capacity | Pressure | Head | Power | Outlet flange | Permitted solids Dia. | Fiber length |

| APG35-2 | 960rpm | 8m³/h | 1.2Mpa | 120m | 4kw | 50mm | 3mm | 40mm |

| APG40-1 | 12m³/h | 0.6Mpa | 60m | 4kw | 65mm | 3.8mm | 45mm | |

| APG40-2 | 12m³/h | 1.2Mpa | 120m | 5.5kw | 65mm | 3.8mm | 45mm | |

| APG50-1 | 20m³/h | 0.6Mpa | 60m | 5.5kw | 80mm | 5mm | 50mm | |

| APG50-2 | 20m³/h | 1.2Mpa | 120m | 7.5kw | 80mm | 5mm | 50mm | |

| APG60-1 | 30m³/h | 0.6Mpa | 60m | 11kw | 100mm | 6mm | 60mm | |

| APG60-2 | 30m³/h | 1.2Mpa | 120m | 15kw | 100mm | mm | mm | |

| APG70-1 | 720rpm | 45m³/h | 0.6Mpa | 60m | 11kw | 125mm | 8mm | 70mm |

| APG70-2 | 45m³/h | 1.2Mpa | 120m | 15kw | 125mm | 8mm | 70mm | |

| APG85-1 | 65m³/h | 0.6Mpa | 60m | 15kw | 250mm | 10mm | 80mm | |

| APG85-2 | 65m³/h | 1.2Mpa | 120m | 18.5kw | 150mm | 10mm | 80mm | |

| APG105-1 | 145m³/h | 0.6Mpa | 60m | 22kw | 200mm | 15mm | 110mm | |

| APG105-2 | 145m³/h | 1.2Mpa | 120m | 30kw | 200mm | 15mm | 110mm | |

| APG135-1 | 350m³/h | 0.6Mpa | 60m | 37kw | 250mm | 20mm | 150mm | |

| APG135-2 | 350m³/h | 1.2Mpa | 120m | 45kw | 250mm | 20mm | 150mm |

It applies to deliver lubricating medium, such as oil, bitumen, slurry, drilling mud with the viscosity of 3-760cSt at a temperature below 350°C.

The pump’s working pressure range from 0.6Mpa to 2.5Mpa.

The flow rate ranges from 0.6m3/h to123 m3/h.

They are mainly suited to fuel delivery, hydraulic engineering, shipping engineering, petrochemical, and other industry fields.

Standard seal: Mechanical seal, packing seal is available.

Direction: CW seems from the motor side.

How to select a screw pump?

Yes. It’s depending on the centrifuge flow rate request. The screw pump APG series holding capacity from 8m³/h-350m³/h. Besides the solids control system, a screw pump can be used in other applications, too. For the drilling mud process, the centrifuge feeding pump is a rather typical use of screw pump. Compared to other pumps, screw pumps holding shorter life or operation life considering the wearing parts. But it’s a compact and high effect, many users prefer it then

Application of screw pump

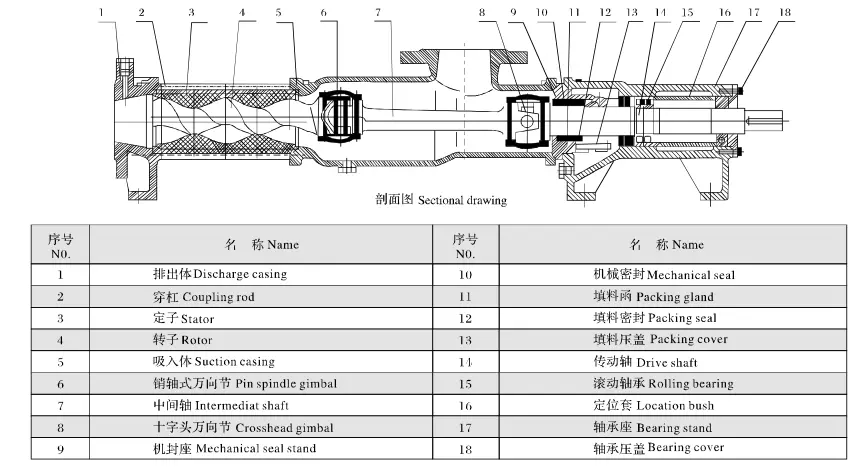

Screw pump mainly consisted of the discharge port, the stator, the rotor, the flexible section, the middle axis, suction room, seal, bearing, driveshaft, bearing body. Among these parts, the wearing parts are the rotor and stator. The screw pump wet parts can be made of stainless, steel, and the high quality rubber. According to different fluids’ content and property, we’ll provide a certain configuration on screw pumps. For example, the abrasive material we kindly suggest use the special rubber instead of stainless steel. As we know, the S.S can’t adapt abrasive material but corrosive material. Compared to other pumps, screw pump is not easy to lead swirl. This helps much to maintain pump capacity. It is not sensitive to viscosity so it is capable to transfer material with high viscosity

Aipu screw Pump features

- Medium is delivered continuously without agitation and pulsation.

- Small vibration and low noise.

- High pressure and high efficiency.

- Simple structure and easy assemble.

- Small volume and lightweight.

- Wearable and long life.

Actually, when the screw axis is rotating, the lower Vroom will become large. Vroom will close against fluid sucked. The closed room will be pushed forward along the axle. Then a new suction cavity generates on suction end. One and one closed cavity move forward, the fluid will be pressed out.

For any question or demand, just feel free to contact AIPU solids. You will get a professional proposal very soon.