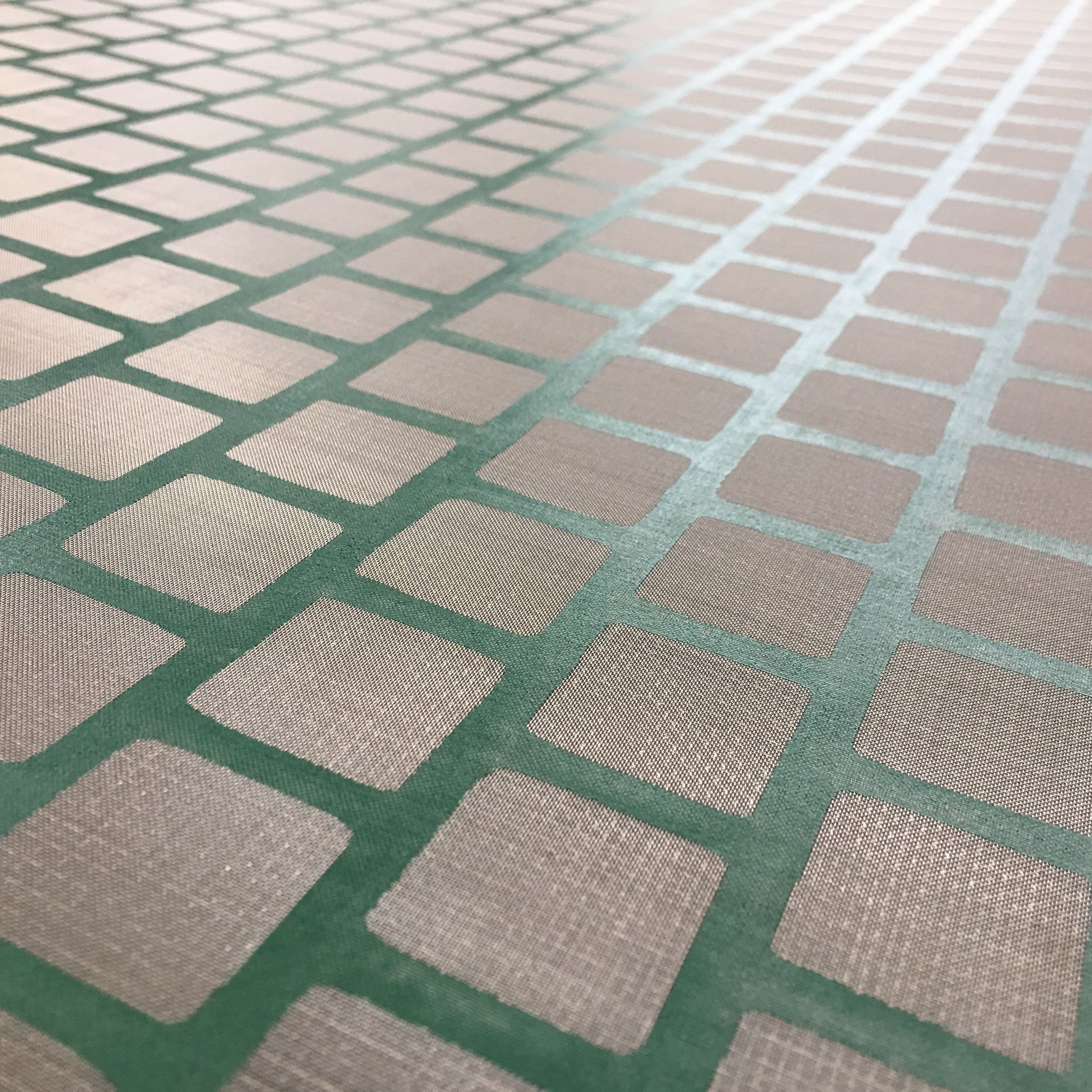

Why maintain shaker screen?

Maintaining your shale shaker screens is as important as the screen selection itself.

Any screen’s service life can be maximized through proper selection and maintenance. Proper screen maintenance starts with regular inspections. Look for tears, signs of blinding, and gaps between the

screen mesh and frame.

For example, if your inspections; show that a screen typically lasts 9 weeks, you can change the screen after 7 or 8 weeks during scheduled downtime and avoid the interruption to your process. Or, if your material has corroded the screen, you can replace it with a screen made of mesh of a different steel alloy or a synthetic

material.

After inspecting the screen, clean it off if needed. The

cleaning method will depend on your material and process

and can range from light brushing of dry, lightweight particles

to power-washing of heavy or cohesive particles from

the screen.

How to select screen mesh and steps of maitain?

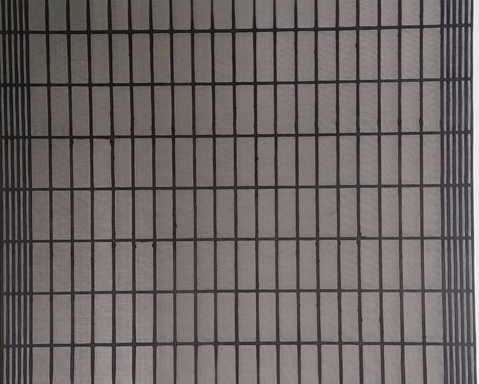

Usually, when the shale shaker is first stage solids control equipment the shaker screen can be 30-100mesh. When the shale shaker is a part of mud cleaner, the shaker screen for the cleaner will be 80-200mesh then.

Of course, the selection is relative with drilling mud property and our working condition at the drilling job site.

Replacement screen steps:

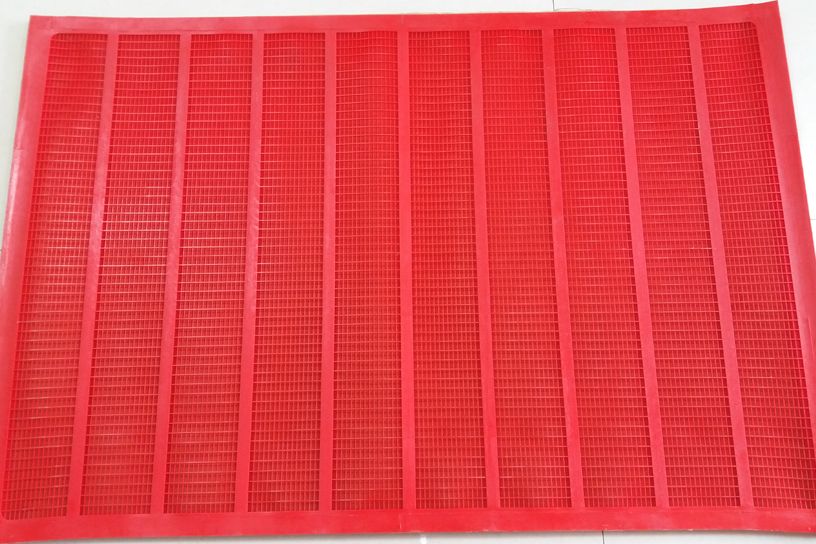

1) Before every shut off, the shaker should run without any medium for 5-10 minutes, at the same time, use clean water to flush screen clean

2) After every operation, the shaker frame and screen should be flushed by water (summer) or steam (winter), there should be not much sediment on shaker frame and shaker screen. Especially when the drilling mud has large viscosity and high density or screen is finer than 60 mesh.

Otherwise, the particles and fine sand on screen will block screen hole, when we start shale shaker, it will decrease filtration result and lead drilling mud flow away, lose much unnecessary cost

How to replace shale shaker screen?

During operation, while the screens are broken , or cannot separately well, it then should be replaced by other shaker screen. Aipu shaker screen can make high quality shaker screens for its own brand shale shaker as well as other famous brand. And also, Aipu can customize screens according to clients certain requirements.