Shale shakers

Shale shakers Mud Cleaner

Mud Cleaner Desander

Desander Desilter

Desilter Decanting centrifuge

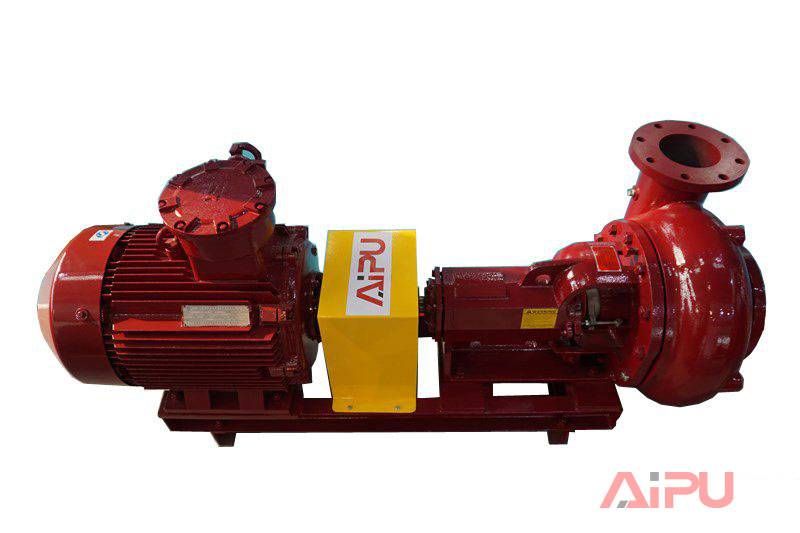

Decanting centrifuge Centrifugal Pump

Centrifugal Pump Vacuum degasser

Vacuum degasser Centrifugal Degasser

Centrifugal Degasser Sheer pump

Sheer pump Jet mud mixer

Jet mud mixer Mud Agitator

Mud Agitator Mud gas separator

Mud gas separator Flare ignition device

Flare ignition device Mud gun

Mud gun Mud tank

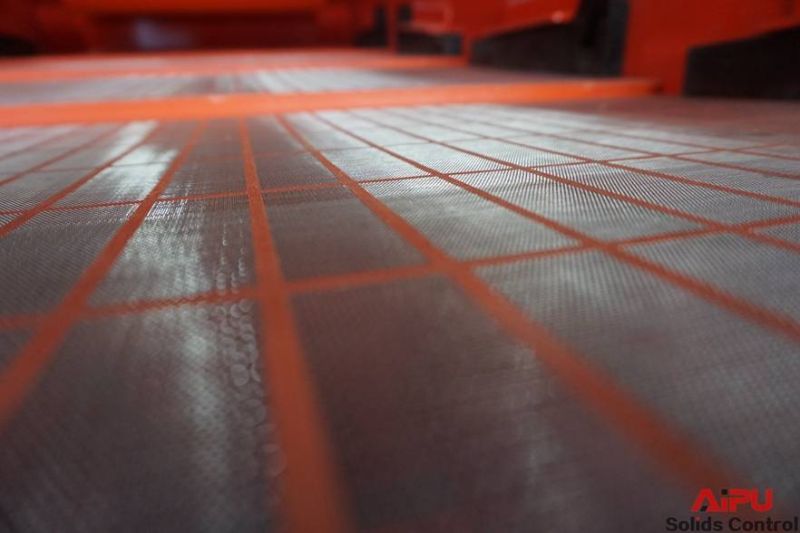

Mud tank Shaker screens

Shaker screensSolid control equipment are also referred to solid removal equipment, which used to remove the solids by mechanical separation method to keep the balance of drilling mud. Solids control equipment including first phase primary solids control using the drilling fluids shale shakers to separate drilled solids coarser than 100 microns. The second phase solids control equipment is desander for separation of drilled cuttings larger than 47 microns, which is made as one number 10 inch desander cone for 500GPM solids control system, two number of 10 inch desander cones for 1000 GPM mud system, and 3 desander cones for 1500 GPM. The third phase solids control equipment is desilters separator for drilling cuttings larger than 15 microns, which are a number of 4 inch desilter cones, for scarce capacity of solids control system. Flow rate is produced by different numbers of desilter cone.

With the development of environmental protection, the closed loop solids control system becomes more popular, after solids control equipment handling, the drilling cuttings should be further treated by drilling waste management equipment like vertical cuttings dryer, linear motion drying shaker. Drilling fluids ultra fine solids should be separated by chemically enhanced dewatering system to clean the drilling fluids to enable it restricted to reuse.

Aipu is solids control equipment manufacturer. Aipu manufactures all series mud solids control and drilling waste management equipment. We are focused on it and provide the optimal proposal continuously to all users in drilling field.

Manufacturing solids control equipment with API standard strickly.

Our equipment had tested by series tough circumstance.

Customeriztion available.

| Equipment | Water/Light Treated Clay | Disperse-Weighted | Un-weighted Non-dispersed | Weighted Non-dispersed | Oil Muds | Preformed Stable Foam | Gas, Air,and

Unweighted Mis |

|---|---|---|---|---|---|---|---|

| Mud Shaker | High G-force shaker with the smallest screens possible. | shale shakers possible. | High G-force shale shaker with the screens possible. | High G-force shaker with the smallest screens possible. | High G-force drying shaker. | No solids control equipment needed. | No solids control equipment is used. |

| Sand trap | 20-30 bbl, with 45° bottom-large diam. dump. | Do no to dump liquid mud. | Important to settle coarse material ahead of desander-desilter units. | Settle coarse material ahead of desander-desilter units is needed. | Important to settle sand. Be careful of mud loss. | No solids control

equipment needed. | No solids control

equipment is used. |

| Desander | Important-run ahead of desilters. | May be used to

remove coarse material ahead of desilting equipment. | Important to prevent overloading desilters or centrifuge | Important to prevent overloading desilters or centrifuge | Can be used by dumping into tank of solvent. | Normally,foam is a one-pass system, foam and solids go to waste sump. | Air and solids to waste sump. |

| Desilter | Important to remove fine silts for low weight. | Not used | Essential for low-solid muds | Not recommended | Not used | No solids control

equipment is used. | No solids control

equipment needed. |

| Mud cleaner | Perfect equipment for remove fine silts for low weight. | Excludes light solids on medium weight mud. | Essential for drilled solids control. | Useful on medium weight muds. | Not used | No solids control equipment needed. | No solids control equipment needed. |

| Decanting centrifuge | Not used | Essential for economic control of

high weight muds. | May be used to reclaim liquid sand

dump drilled solids. | Essential for high weight mud control. | Can be used to reduce weight. | No solids control equipment needed. | No solids control equipment needed. |

| Degasser | May be used ahead of treatment if gas encountered. | Essential in kick control for true mud weights. | Essential for good kick control practice. | Essential for good kick control practice. | Can be used if gas cutting a problem. | Can use gas trap to

separate gas and liquids. | May use low pressure trap to reclaim gas. |

| Mixing hopper | Minimum required for mixing clay, gel, chemicals. | Maximum for rapid weight increase on kicks. | Maximum required to mix polymers;

located after solids control. | Maximum required to mix polymers;

located after solids control. | Maximum required for mixing new mud. | Not required unless

additives used. | Not needed |

| Stirring and agitation ( Mud Agitaors, Mud Gun ) | Adequate for lost

circ. material, top

guns best. | Essential to prevent settling. | Important to maintain uniform system. | Important to maintain uniform system. | Essential to prevent settling and maintain viscosity. | Needed if additive

used but not after foamer added. | Not needed |