We just delivered about 400 panels shaker screens to Dubai. They are our new client…

2020

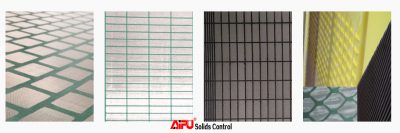

Reliable Shale Shaker Screen Certified By API RP 13C For Oilfield Shale Shaker

Shale shaker screen is the most important and necessary wearing spare parts for oilfield shale shaker and mud cleaner. The function of a shale shaker screen is to remove the particles bigger than the screen opening, and recover the usable drilling fluids which will go through the screen openings and get back to the drilling mud recycling system.

There are many brands shale shaker and mud cleaner, and every brand has his own design and own sizes shale shaker screens. In order to control the mud weight accurately, how do the mud engineers choose the right screens openings from different shale shaker and shale shaker screen suppliers?

In order to solve the problem, a general standard is necessary for design shale shaker screens. API RP 13C is an international popular standard to define the shale shaker screen specifications. A authorized lab will test a shaker screen by using a specific test procedure (as described in API RP 13C), the lab test will define a series of specifications of the screen, like D100 cut point, screen conductance, non-blanked area. After these specifications are confirmed, the API Screen Number is determined. It ensures that, all Shale shaker screens confirmed to API RP13C standard, if the API No. is the same, the screen cut point will be the same. Same model screens from different screen suppliers if with the same API NO., the screens are interchangeable.

Below definitions are some important parameters of shale shaker screens to help you know more about API screens:

API screen NO.: After testing a screen by using a specific test procedure (as described in API RP 13C), the API screen no. is determined.

Mesh: it relates to a piece of screen wirecloth, is a measure of the number of holes in a linear inch (such as 100 mesh) or in a linear inch in each direction (such as 100 x 60 mesh).

D100 Cut Point: The D100 cut point of a screen is the largest particle size which will pass through the screen opening. D100 means 100% percent separation.

Screen Conductance: It measured in kilodarcies per millimeter (kD/mm), defines a Newtonian fluid’s ability to flow through a unit area of screen in a laminar flow regime under prescribed test conditions. All other factors being equal the screen with the higher conductance number should process more flow.

Non-Blanked Area: The non-blanked area of a screen describes the net unblocked area in square feet (ft²) or square meters (m²) available to permit the passage of fluid.

Aipu Solids Control makes API RP13 shale shaker screens for different shaker brand. May you have any questions, welcome you contact Aipu Solids Control for inquire.