Aipu shaker screen has made shaker screens so long time according to API shaker screens…

2020

Shaker Screen API Size VS Mesh Size

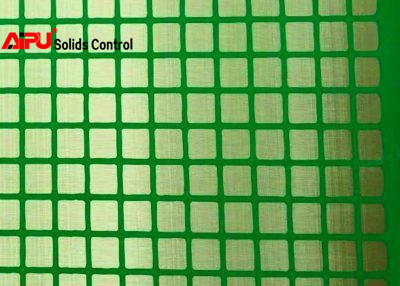

Shaker screen is the most important parts for shale shaker. Suitable screen size and reliable screen quality can greatly reduce drilling cost. And good design shale shaker can prolong lifetime of shaker screen. We, Aipu solids control shaker screenis certified by API RP13C

Screen size usually indicated by mesh size or API size. Many clients wonder: what is difference of mesh size and API size? In order to get a clear point on the API number and mesh number regarding the shaker screen, here let’s see more professional point.

Definition of mesh size:

Mesh count is the number of opening per inch in directions perpendicular to each other and parallel to the screen wires. For example, a 40-mesh screen would have 40 openings per inch in one direction and 40 openings per inch in a perpendicular direction. In an effort to eliminate calling the screen a “40 by 40” screen, the common terminology resulted in calling the screen a 40-mesh.

API size

In an effort to better describe multilayered shaker screens, API issued API RP13.

API is used to identify the largest solid that would pass through each screen (or the smallest solid captured by the screen); this is called D100. Solids smaller than D100 will pass though a D100 screen. Each screen manufacturer have its own D100 count (screen openings microns), but the micro court should among the same scope related a a certain API count. For example: D100: 137.5 ~165.0 equaled to API 100.

Above is just brief information or simple way to identify and learn the mesh size and API size on shaker screen. If you do need details or you have any questions ,just contact us freely.