Shale Shaker Screens are one of the major business for Aipu Solids Control. We understand,…

2020

Shaker Screen Certified By API RP13C

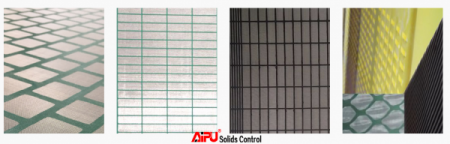

AIPU manufacture a complete line of replacement screens

Shaker screens as the most cost spare part of shale shaker are very concerned by engineers. AIPU shaker screens manufactures a complete line of replacement screens for all shale shakers in the oil field drilling industry. Whether your shale shaker is linear, elliptical or a circular motion machine, AIPU can provide a quality screen for you.

We, Aipu solids control has 18 years experience manufacturing shale shaker screen. Our Screen has been tested under API RP13C. Trust the accurate cut point will lead better performance and longer service life of screen.

For maximum efficiency, the solids on the screen surface must travel in a predetermined pattern “spiral, elliptical, orbital or linear motion” in order to increase particle separation efficiency and reduce blockage of the screen openings. So both screen cloth and frame must be reliable to fit different solids in various drilling circumstances. Generally, the materials of screen cloth is stainless steel and polyurethane. There mainly has two materials component screen frame: steel, composite frame.

Our engineers and design professionals can help supply shale shaker screen with a variety of mesh ranges for certain application during whole well drilling process. Aipu featured new products include replacement composite screen for Mongoose shaker for Cobra series screen, etc. The layers of stainless steel wire mesh are well arranged to achieve optimum filtration efficiency and conductance.

API screen label

Screens conform to API RP13C is requested to indicate information as below. API Designation, manufacturer screen model number, cut point(D100), the manufacturer name, origin.

The NBA and the Conductance is not a must item indicated on label. Besides above information, some of the screen tag also indicate the produce date, batch number, packed screen quantity per carton.

Many clients don’t understand difference between API designation and mesh size. Considering the convenience and interchangeability on screen use, API size does help much on screen selection. For example, when we drill an oil well at 2000m depth, the solid content is main sand. The screen size may request API 170. So, when we replace screens the size should be API 170 but don’t need to consider the mesh size or the different configuration. We need to consider the particle size and separation point will be ok