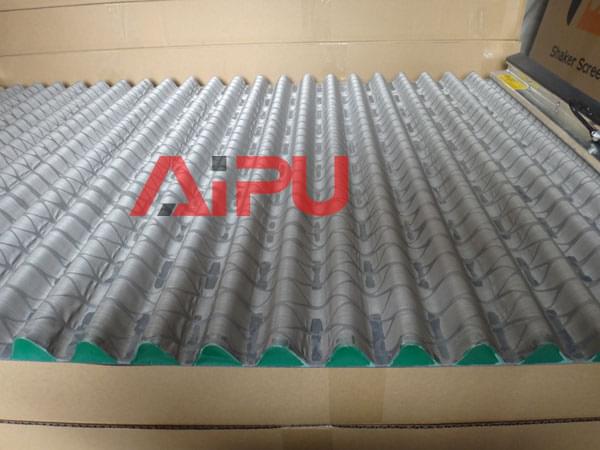

We are gonna deliver one set shale shaker for European client. They ordered the shaker…

2018

Shale Shaker Screen | How To Select And Use Proper

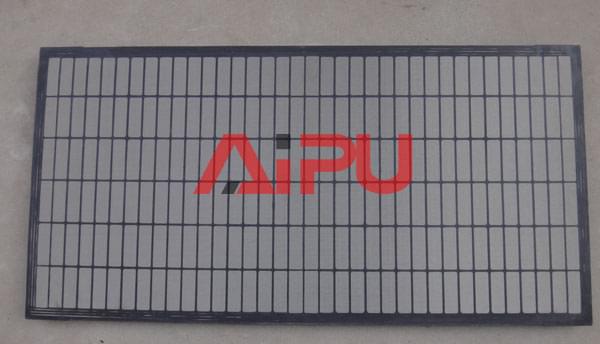

Shaker screens are one of the most important and overlooked the pieces of equipment on the drilling rig. The shale shakers are your first line of defense against drill solids and your primary solids control equipment.

Shaker screen is a key factor in determining the success of your controlling mud and cuttings. It is very important to have the right shaker screen selected for your formation cuttings bid type and mud properties.

Select Shaker Screen

On surface hole, drilled solids are usually larger which can be easily removed with a coarse mesh shaker screen, a mesh of 50 84 or 110 is usually adequate. However, intermediate and main hole cuttings are typically finer. Therefore it requiring a finer mesh. I would recommend a minimum of a hundred and ten and beyond for very fine sand. The screen selection will also depend on ROP(rate of penetration), How well the hole is cleaning and if you’re adding else products which you may want to reuse to the system.

Use Screen Proper

Maintaining your shaker screens are as important as the screen selection itself. In normal drilling, it is important to ensure that the fluid comes about twenty-five percent to fifty percent of the way across the furthest screen from the flowline. Try to have the shaker deck as level as possible. This will allow for more consistent where across the screens and typically means that the right size mesh has been selected. Jacking or raising the shaker deck up increases the amount of time that the solids will be on the shaker screens closer to a flow line. This will decrease the shaker screen life.

Be careful when cleaning screens not puncture the mesh as this will diminish the effectiveness of the screen. The shaker screen with the top layer of mesh gone is also less effective and should be replaced what a shaker screen has a hole in it. there is no protection against drilled stones. why leave things to chance? This will have a dramatic effect on your drilling fluid.

Solids control has a wide range of benefits including, but not limited to:

- Increased drilling penetration

- Reduced mud costs

- Decreased disposal costs

- Increased bit life

Replace Screen

Replacing a shaker screen is a lot cheaper than replacing a mud system or rebuilding mud pumps and directional tools. Enough to mention increased costs on the completion side of the well. It is also important to ensure that shaker deck, rubbers shaker bypass and other components are in good working order at all times. If you open the bypass while drilling all the shales goes underneath the shakers and into the mud tanks providing zero efficiency.

The shale always manages to end up in the screen box of the feed pump which reduces the amount of volume process by the centrifuge. The screen box is a great indicator, the more effective the shaker screens the more successful the centrifuge will be. Centrifuge’s G-forces are not rock crusher crushers or magical machines. The contrifuge will help to dramatically reduce mud costs, transportation costs, completion costs and miscellaneous cost of rebuilding equipment.

Try these tips for increased success on your current or next drilling solids control project.