Introduction of APMGS poor boy degasser AIPU Solids control is a professional manufacturer of poor…

2023

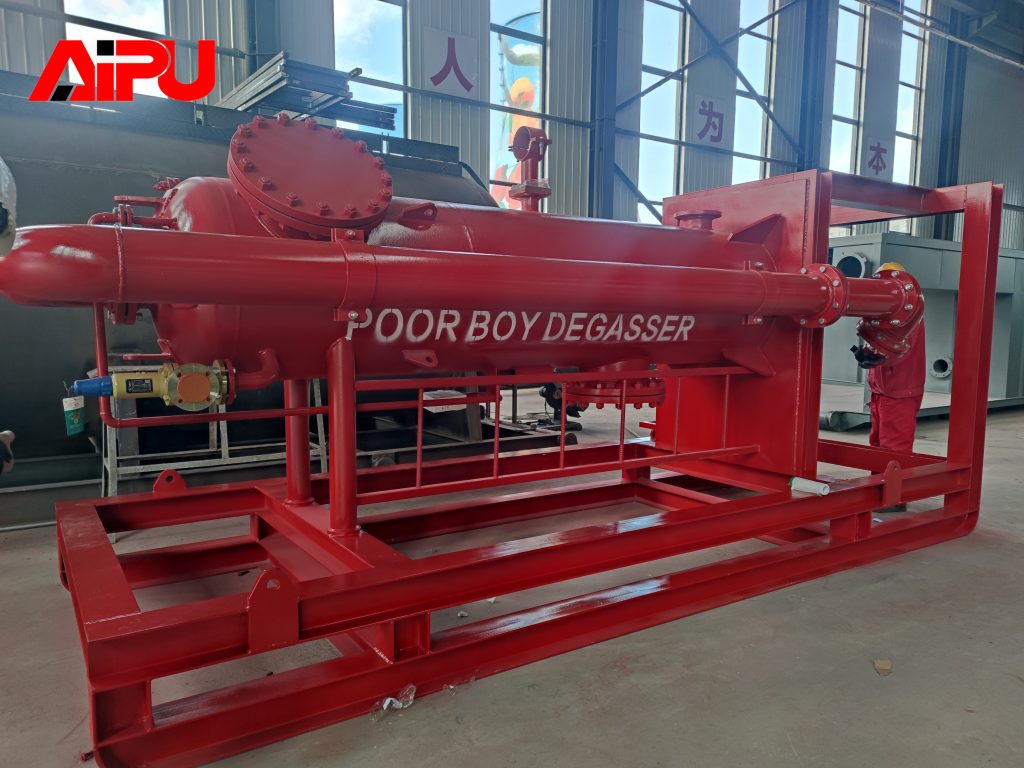

Vertical Well Control APMGS800 Poor Boy Degsser

Poor Boy Degasser

What’s the role of poor boy degasser in solids control system? Poor boy degasser is used before shale shaker. If the drilling fluids was found to be invaded by dangerous gas through a testing device, drilling mud will flow into the poor boy degasser to process first through the choke manifold.

Poor boy degasser is also called mud gas separator is the first stage professional equipment to treat the gas invade mud. It is mainly used to remove the big bubbles with a diameter of more than 3mm. Most of these bubbles are the expanded gas filled in the drilling fluid in the annular of the wellbore. It would cause a well kick if not to remove it timely.

Pooy boy degasser is located downstream of the choke manifold, and is vertical installed near the shale shaker.

Poor boy degasser APMGS800

| Model | APMGS800 |

| Vessel diameter | 800mm |

| Flow rate | 240-280 cubic meters per hour |

| Inlet line | 5″ |

| Discharge line | 8″ |

| Vent line | 8″ |

| Color | AIPU color |

APMGS800 means the poor boy degasser is holding a vessel diameter 800mm. It is a popular model than other degassers. The treating capacity is up to 260m³/h. The degassing efficiency is up to 95%.

With mud’s separators, there are two main types. Also known as a ‘poor-boy’ and a ‘gas buster’, the more common of the two is called an atmospheric mud/gas separator. However, some mud/gas separators are designed to operate at moderate backpressure. Although these will mostly operate under 100 psig, it’s possible to come across those that work at the atmospheric gas vent line pressure plus the vent line friction drop.

Main configuration of degasser APMGS800

The vessel diameter of the mud gas separator is 1000mm, the inlet and discharge line is 5”, 8”. While the gas vent line is 8”. The overall dimension of the whole degasser is about 2000x2000x6000mm. The vessel material is made of special carbon steel Q345R to resist the H2S. and it can be stored at -50° to +50°

one complete poor boy degasser including degasser body, skids, pipelines, safety valves, and pressure gauge. Some customers may request counter flanges and seals, we can provide these spares against requirements.

Mud gas separator is made of steel sheet thicks 10mm for normal pressure working conditions. Some of the degassers are made of steel sheets thick 14-20mm per different working pressure requirements. The pipelines and the valves will be different from normal pressure degasser as well.

Why do we need the mud gas separator?

For oil and gas well drilling, we usually set mud gas separator ahead of shale shakers. The drilling mud out of the well-bore will flow into the degasser via the chock manifold. After degassed, fluid will flow out of the degasser into a shaker by pass or possum belly. Degasser will help get rid of large quantity invading gas. These are harmful and toxic gas may lead blow out

Especially when we drill the gas well at the gas field. The degassing is very important to safety working. We use the poor boy degasser and vacuum degasser together to control the gas volume entrained in drilling fluids and remove them efficiently.

Application of poor boy degasser APMGS800

Poor boy degasser will work with flare ignition device to burning the discharged gas 30 or longer distance away. The flare ignition device will connect with degasser with gas vent line, the flare ignition device is non return valve, ignitor, junction box and control panel with cable. AIPU Solids Control is one of the leading manufacturer for mud gas separator, flare ignition device as well as other drilling mud process equipment like shale shaker, mud cleaner with cyclone and shaker, centrifuge, etc.

Is there another type or model poor boy degasser?

Yes. There are APMGS1200, APMGS1000. The difference is the diameter of the line’s diameter and the vessel thickness. Based on working conditions, there are normal pressure degasser and middle pressure, high-pressure degasser. And the working pressure can be 0.1Mpa to 6.4Mpa, or even higher according to practical condition.

Besides the normal standard poor boy degasser, there are some degassers that can be customized. For example, we have made the APMGS500, APMGS600 degassers for clients request smaller degasser and smaller flow rate. Please feel free to let us know the requirement of your degasser.

There is a customizable configuration of the mud leg. That means the U tuber or mud seal length for a degasser. The mud seal will help to prevent gas flowing out of the degasser during operation. For the degasser leg and base, we can configure it as the adjustable one. That means the laydown leg and the supporting base can be configured flexibly.

For any question or demand, please feel free to contact AIPU solids. You will get a free offer on an optimal solution, you will get a professional proposal very soon.