Shaker screen is the most important parts for shale shaker. Suitable screen size and reliable screen…

2020

API Screen With Different Mesh Size Of Shaker Screens

API screen information

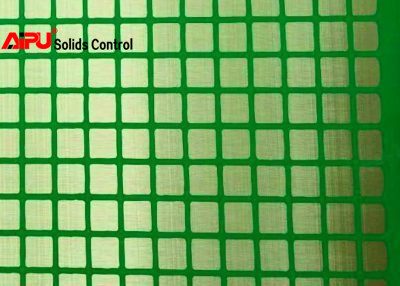

API screen means the shaker screen mesh size conform to API RP13C. We know there are so many different models and makes of screen.

For API shaker screen information , which mainly including the cut point, conductance, non blanked area. But the key issue is the cut point. The cut point reflects how big solid can be filtered out of drilling fluid. API number of shaker screen indicates a range of drilling cuttings will be separated out completely.

For example, API 140 screen means this screen can filter particles 98-116.5 microns out. So, we found Derrick DX175 and HP180 mesh designation are both API 140 conformance. Furthermore, Derrick DX and HP mesh configuration are available fro almost replacement shaker screen. That means, API screen size won’t be affected by shaker screen makes or model

Different mesh with same API number

API RP 13C aimed to give a clear and standard guidance on screen selection and exchange. Different shaker screen manufacturer will fabricate screens with different mesh configuration. And they will have certain part name or part number.

Take NOV Brandt RDH 280 as example, and the M-I SWACO XR270. They are different mesh size of different shaker screen model. However, they are both same API 140 as Derrick DF-A140 and DX-A140. May many users say, they do have other different designation, such as the exact cut point, the non blanked area and the conductance.

Just as we talked before, API size mainly and generally give us a standard cut point range. There is no exact standard tell us how much conductance or non blanked area.

Other information about API screen mesh difference

Even by same manufacturer, they will have many different meshes with same API size screen. The NOV Brandt VSM300 screen, there are PXL series screen, the RHD screen, as well as the XF screen. The difference including the different mesh configuration, the screen pattern, the screen layers, the diameter, etc.

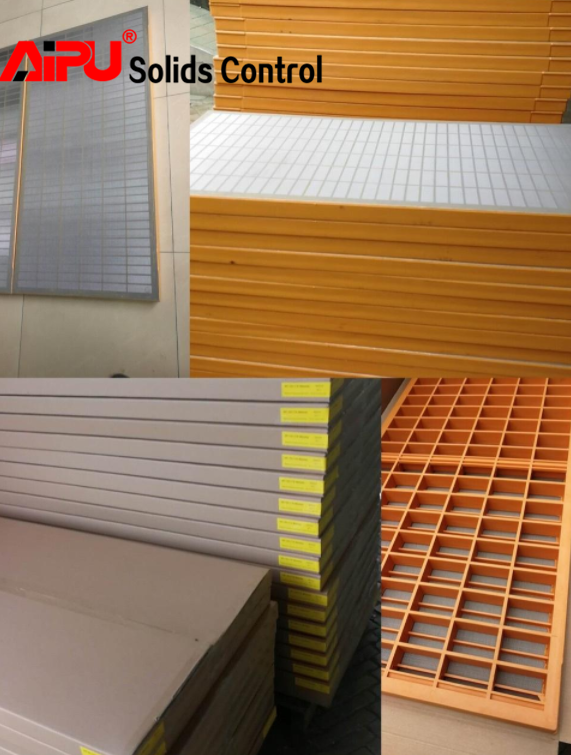

Aipu shaker screen introduction

What is written above is just a brief introduction about the connection between screen API and mesh. If you want to know more and more detailed information about them, please contact Aipu directly. Our main technical team have been focusing on the solids control industry for more than 20 years. We, Aipu solids control has 18 years experience manufacturing shale shaker screen. Our Screen has been tested under API RP13C.

Our engineers and design professionals can help supply shale shaker screen with a variety of mesh ranges for certain application during whole well drilling process. We are able to produce various kinds of replacement shaker screen for different makes and models shaker. Welcome you make an inquiry.