Brief of high strength oilfield drilling rig mats Oilfield drilling rig mats are made of…

2022

High Strength Oilfield Drilling Rig Mats

High strength oilfield drilling rig mats summary

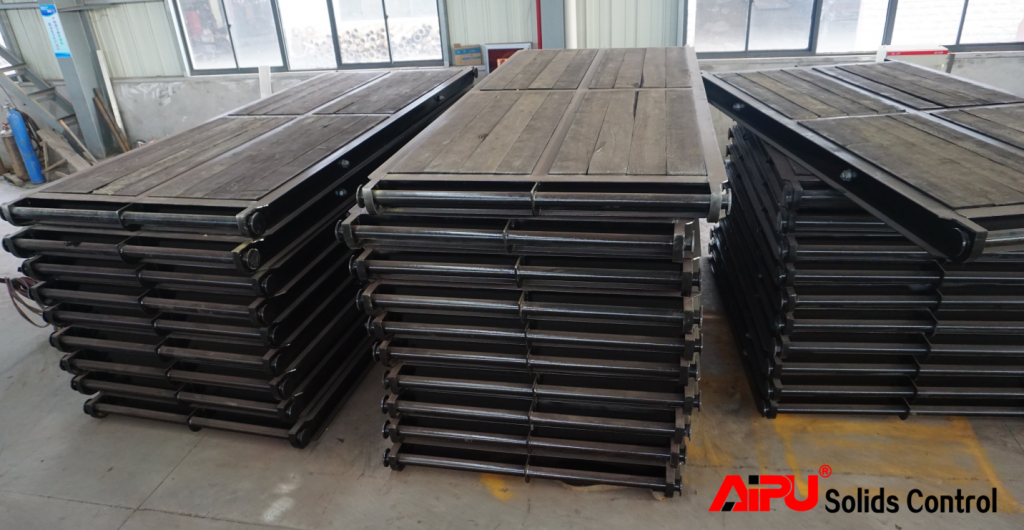

Almost rig mattings are wood and steel mats or steel frame mats. These mats are commonly made of spruce, pine, fir or a combination thereof encased in a steel frame. The frame is normally I Beam or H beam steel. The steel is used to strengthen the mats, enabling the manufactures of the mats to build them in larger sizes and to support more weight compared to all other types of mats. Common sizes are 8’x10’, 8′ x 20′, 8′ x 30′, and 8′ x 40′. The size is also flexible and custom designed. One great advantage is the ease of repairing the wooden inserts which gives new life to an already long lasting and durable mat

All rig mats produced by Aipu solids control will be qualified and reliable. We do followings to give users confidence.

1. The raw material. Including the steel and the wood. Selected strictly according to executive code.

2. Wood will be processed under anti-corrosion procedure

3. We do the inspection and all process step by step to ensure users high performance products.

4. Painting the rig mats with famous brand marine coating oil, which is high anti-corrosive.

5. Custom built size and design as per clients’ demand.

Oilfield drilling rig mats specifications

| Model | Length | Width | Height |

| APGM204 | 2000MM | 2000MM | 200MM |

| APGM205 | 2500MM | 2000MM | 200MM |

| APGM203 | 3000MM | 1000MM | 200MM |

| APGM206 | 3000MM | 2000MM | 200MM |

| APGM209 | 3000MM | 3000MM | 200MM |

| APGM208 | 4000MM | 2000MM | 200MM |

| APGM210 | 4000MM | 2500MM | 200MM |

| APGM212 | 4000MM | 3000MM | 200MM |

| APGM216 | 4000MM | 4000MM | 200MM |

| APGM214 | 5000MM | 2000MM | 200MM |

| APGM215 | 5000MM | 3000MM | 200MM |

Oilfield drilling rig mats standard

The executive code including wooden materials, hot rolled steel beam, metal welding quality requirements, anti-corrosive wood, drilling site layout, drilling equipment basic specification, and so on

Suggested size including 5x2m, 3x2m, and 4x2m. 5x2m is suitable for base. The steel beam should be I beam larger than 16# or H beam larger than 175#. Wood material strength should be higher than 32.8MPa.

The wood beam on mats should be higher than steel frame 10-20mm both upside and backside. Steel beam surface painting oil film thicks above 150microns. The welding quality should conform with GG/T12467.4 or equivalent

How to test and inspect oilfield drilling rig mats

Put the mattings on flat ground with strength loading over 0.15MPa. Then lay materials on the mats gradually last 10 minutes. During whole test check if any deformation or cracking on the rig mats.

The spot inspection is based on 40 panels per batch. Each batch mats should select 2 panels by chance. If any non-conformance happened, there should be another check on 2 panels again. If still any non-conformance, we define this batch mats are not qualified.

We will deliver about 100 panels rig matting board to an African oilfield drilling site. End user request strictly on whole quality and inspection. They will despatch SGS people to inspect mats per their requirements and agreement

Aipu can produce rig mattings according to clients’ certain requirements. Any demand? Please let us know