As we know Aipu solids control focus on solids control industry about 20 years. Today…

2021

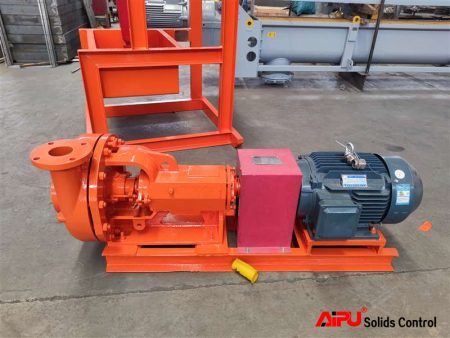

Reliable Horizontal Centrifugal Pump For Well Drilling Mud Solids Control System

Centrifugal pump definition and general information

Centrifugal pump is also called sand pump. We all know that centrifugal pump play an important role in the mud solids control system of drilling platforms. Supply slurry for dedander and desilter, provide power for mixing equipment, etc

Centrifugal pump is one of important equipment in solids control system. With double seal design, strict foundry technology to ensure the stable performance and low failure rate; double seal with filling and mechanical, better seal result and long use life; double lubricating bearings ensures long-term operation of the pump and low maintenance costs. Part of pump spares can be interchangeable with Mission, universal use and convenient maintenance.

Specification of APSB series centrifugal pump

| Model | Flow Rate | Head | Power | Speed | Efficiency |

| APSB8x6-14 | 320 m3/h | 40m | 75KW | 1480rpm | 65% |

| APSB6x5-13 | 180 m3/h | 34m | 45KW | 1470rpm | 60% |

| APSB5x4-12 | 90 m3/h | 30m | 22KW | 1460rpm | 60% |

How centrifugal pump works

Applying classical mechanics theory, assuming viscosity of the liquid equal 0 and no energy loss for the work of energy transferring from impeller to the streamlines which means that, all separate flow will be uniforms (this approximations of physical reality to get the simpler as solid state mechanism than hydraulic mechanism

General explanation: Like most pumps, a centrifugal pumps convert rotational energy, often from a motor, to energy in a moving fluid. A portion of the energy goes into kinetic energy of the fluid. Fluid enters axially through eye of the casing, is caught up in the impeller blades, and is whirled tangentially and radially outward until it leaves through all circumferential parts of the impeller into the diffuser part of the casing. The fluid gains both velocity and pressure while passing through the impeller. The doughnut-shaped diffuser, or scroll, section of the casing decelerates the flow and further increases the pressure

In the drilling fluid solids control system centrifugal pumps are used as transfer pump. Mainly pump drilling fluid to desander hydrocyclone, desilter hydrocyclone. They also are combined together with mud hopper to be jet mud mixer or mud mixing pump. Pumps work as power transition tool.

Features and benefits of centrifugal pump

¤ Semi-open impeller design, high efficiency and flow

¤ Combined seal with mechanical and packing, good perfermance and low maintenance cost

¤ Pump with high quality iron material, and impeller with high chromium alloy, long use life

¤ Stable operation and low noise

Centrifugal pump types in solids control

Drilling fluid solids control requests many centrifugal pumps to be fit on mud tanks. According to function, we call centrifugal pumps as sand pumps, submersible slurry pumps, shear pumps, charging pumps, etc. They are defined for their different functions, but their working principle is the same

Usually in drilling fluid solids control there are horizontal centrifugal pump and vertical centrifugal pump. The difference is motor installation direction and pump feed inlet position.

To select either of installation way we need to consider the actual operation condition and general space. Presently, except installation way, there are different types pump on the seal. Mechanical sealed pump are more popular since the stable performance and reliable quality

We may face many different problem during pump operation. Please contact us for further information or support. We Aipu solids control will do come to you with optimal solutions

What Centrifugal Pump Work For?

Trip Pump: Trip pump will sit at trip tank to transfer mud from trip tank into drill hole directly in special conditions. The pump normal driven by 11 or 15kw electrical motor with a 4×3 size pump. The mud flow 200 to 250GPM is enough.

Desander & desilter feeding pump: It is normally 8×6 size pump driven by 55kw motor for 1000GPM mud flow for oil and gas drilling, but 6×5 or 5×4 size pump with smaller electrical motor will be used for smaller mud flow capacity for oil & gas drilling, coal bed methan drilling, horizontal directional drilling or water well drilling.

Water pump: The water pump will set on water tank with water line supply to solids control mud tank. A diesel pump may work as standby incase of fire.

Mixing Pump: The mixing pump normally 8×6 size driven by 55kw electrical motor to supply mud to mixing hopper for new mud mixing application.

Charge Pump: 1 or 2 set charge pump will sit beside mud pump for charging application.

Centrifugal pump is well used in drilling mud process system because it’s high efficiency, easy maintenance and cost effective. AIPU Solids build a complete line for drilling mud process system as well as all sizes centrifugal pump. Please contact us freely for inquiry or technical support.