shaker screen

2020

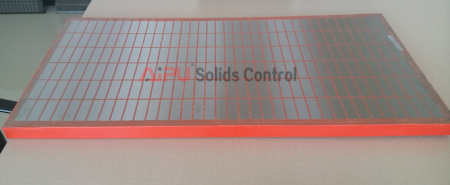

Well Drilling Mud System API RP13C Shale Shaker Screen Replacement

Shale shaker screens are the important wearing parts for whole mud system and even a whole well drilling project. We know the screen is the main consumption in a whole solids control system. Some screens even only are used for 20 hours. This is not meanting the poor quality but the working condition is too difficult.

We, Aipu solids control has over 18 years experience manufacturing shale shaker screen. Our Screen has been tested under API RP13C. We are only China screen manufacturer got API RP13C compliance report. Trust the accurate cut point will lead better performance and longer service life of screen.

APD6 screen replacement

APD6 shale shaker screen is the replacement screen for DP 600 shakers. AP600 screen for DP 600 shaker provides users longer service life at a cost-effective price. The AP600 replacement screen for DP 600 shaker ensures longer screen life and accurate cut point designation in compliance with API RP 13C. Please find the following specifications for more reference.

Replacement D500 screen

APD5 shaker screen is the right fit replacement screen for FLC 500 shakers. APD5 Replacement screen for FLC 500 shaker provides users longer service life at a rather competitive price. Please find the following specifications for more reference.

Replacement screen for 500 series shaker, available in PWP, Pyramid panels, are used on all 500 series shale shakers. The FLC 500’s innovative single-side tension system reduces screen panel replacement time to less than one minute per panel. This faster, easier, and more reliable screen panel tension is provided by tension fingers and two Quick-Lok 1/2-turn tension bolts on each screen panel.

The APD5replacement screen for FLC 500 shaker ensures longer screen life and accurate cut point designation in compliance with API RP 13C.

Replacement Hyperpool screen

APHP shaker screen is the replacement screen for the Hyperpool screen. It is more and more popular. Compared with other screens, it combined with the convenience and steady installation. Aipu produces high-quality HYP screen replacement. Longer service life at cost-effective price assured. Please find the following specifications for your reference.

Aipu D48-30 screen replacement

Aipu produces a high-quality replacement 48×30 shaker screen. It is a replacement for 48×30 screen including the flat and pyramid type. The popular mesh size is from API 40 to API 325.

48330 Shaker screen fits all FLC 2000 of 3 and 4-panel shale shakers, FLC with AWD, FLC Plus HI-G® Dryer, and the Cascade 2000. Please find the following parameters of the replacement 48×30 series shaker screen. Fast, easy, and reliable screen panel tensioning is provided by two pairs of rapid-Change draw bolts on each side of each screen panel. The available screening area per API RP 13C for the FLC 2000 3-panel is 24.9 square feet with the pyramid screen. Kindly find below information for more reference.

polyurethane shale shaker screen replacement

APU urethane screen panel is more and more popular. They are interchangeable with Polyurethane Screens. APU polyurethane screens combine long life, and better performance rivaling that of conventional woven wire screens. Moreover, its anti-blinding properties now make it feasible to screen materials previously considered difficult or even impossible to screen. Since it is more durable than common wire woven screens, the cost-efficiency is rather high. Presently Aipusupply polyurethane screen with below openings.

The polyurethane screen is a core part of the fine mesh vibrating screen. It directly affects screening efficiency and screening performance. Our polyurethane screen surface serves in longer life, anti-blinding, non-leakage. It increases the mineral recovery rate, widely utilized in mining, civil construction, etcetera applications. Both suitable for dry and wet materials

Briefs of Aipu shaker screen

Our screens for the M-I SWACO BEM-600, BEM-650 shale shakers offer higher throughput rates as well as longer life, lower weight. Higher throughput rates reduce operating costs by optimizing shaker performance, while longer life translates into lower screen-replacement costs.

Shale shaker screens are important consumable parts. The screen panel is important to shale shakers. High-quality screens will help the shaker to get great performance. The accurate cut point prevents certain particles and cuttings to drop down into the mud tanks affect the further process or impact the property of the fluid.

Shaker screen life varies because of shaker conditions, mud condition, drilling condition, and the operator, etc. That means if the screens were from one batch and holding the same mesh size but life lasts different there might be the above reasons. For example, we drill an oil well in Kuwait use the OBM the extra thin screen cloth will help to get better penetration or conductance and leadless mud block or mud overflow but the life may be shorter since the fragile wire. When we use screens holding the same API size and the same configuration at some Yan’an oilfield sites use WBM, the screen life will be much longer. Since the general viscosity and mud condition is better than in Kuwait.

Some users find even everything is the same, the screen life performs differently. Please do check again, the shaker’s condition, such as the tensioning system, the bed seal, the spring condition, etc.. Besides, the shaker operator professionality is important. Some workers can handle screens professionally and easily, but some of them even don’t know to clean and put screens in the right places after every shut-off.

The mud engineers will test drilling fluids time by time. This will tell us how to do further process. They don’t check active mud property but also check the disposed of mud. They will evaluate whole mud volume and general mudflow situation. The capable mud engineers give the optimal suggestion on mud use and screen use. Finally, we’ll get the optimal solution on solids control for whole good drilling and save necessary cost

What screens do AIPU Solids produce?

We make screen panels for our Hunter series shaker. Including MG, D, and Miniseries. Furthermore, we provide replacement shaker screens for a famous model, such as 500, 2000, Mongoose, MD, KC, and so on. And the screen panels including the flat pattern, corrugated pattern. The frames can be metal framed or composite frame. The Installation way including the hook strap and the wedge blocked one.

Besides the existing model and brands, we are also willing to provide the ODM and OEM screen panels for clients. Tell us your shaker design, the screen panels you may prefer. Combine your demand and our professional suggestion then you’ll get the optimal solution on shaker screen. Even the solution to your shaker and system.

Aipu shaker screens are of high quality and API RP13C conformed. Screens tested by the professional lab. The API sized screen will provide convenience to select proper screens. As we know the API designation of the screen is a range of cut points under the D100 standard. Every range means the possible high-performance at different drilling section and condition

Please feel free to contact AIPU for more information on shaker screen panels. No matter you need price, or a picture or any question. Just come to us for all solutions of shaker screen